The Ultimate Guide To Premier Aluminum Llc

The Ultimate Guide To Premier Aluminum Llc

Blog Article

The smart Trick of Premier Aluminum Llc That Nobody is Discussing

Table of Contents3 Easy Facts About Premier Aluminum Llc ShownAn Unbiased View of Premier Aluminum LlcPremier Aluminum Llc Fundamentals ExplainedPremier Aluminum Llc - TruthsExamine This Report about Premier Aluminum Llc

When selecting a light weight aluminum foundry for your manufacturing needs, it's essential to study a number of aspects. Among one of the most important aspects to think about is the experience and skills of the foundry. Selecting a shop who has the right understanding of the aluminum spreading procedure, and the profile to show for it, helps to have an effective end result for your project.Having the experience and industry expertise to engineer your spreadings for optimum production and high quality outcomes will certainly enhance the project. Making aluminum castings calls for a complicated set of procedures to attain the best outcomes. When determining on a new light weight aluminum factory to companion with, ensure they have extensive market experience and are educated concerning all aspects of the aluminum casting procedure: style, production, material evaluation, and product screening.

The foundry needs to also have a proven performance history of supplying exceptional items that meet or go beyond consumer expectations. Quality control ought to likewise go to the top of your listing when picking a light weight aluminum shop. By working with a certified factory that follows the criteria for top quality control, you can secure the honesty of your product and guarantee it satisfies your requirements.

About Premier Aluminum Llc

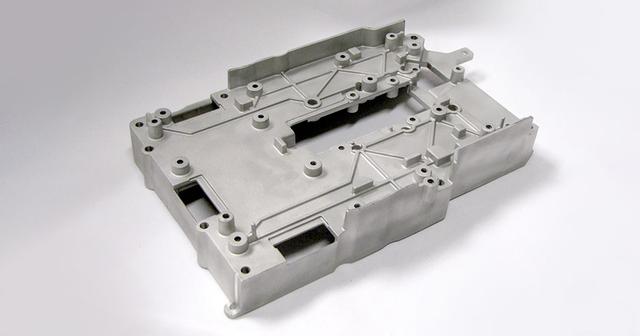

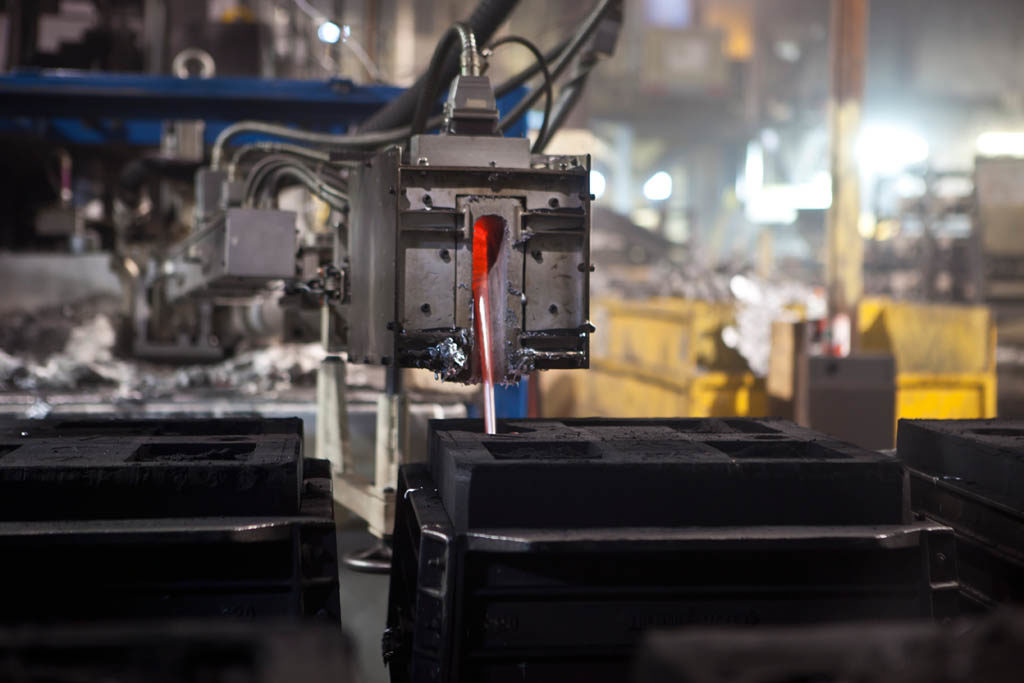

This particular process can be automated and duplicated. Different components that really complicated forms can be made utilizing this process. Subsequently, big quantities of parts can be generated in simply a brief amount of time. Before you start looking for a trustworthy light weight aluminum die caster, there are some crucial things that you require to do initially.

You have to ask yourself what kind of light weight aluminum die spreadings you need. After identifying what you need, you have to mention the requirements of the light weight aluminum die castings you call for.

Do you understand just how much cash you have to invest in the products? In order to do this, the very best thing to do is to establish the amount of aluminum diecasts you need. After having this information, you can start looking into light weight aluminum die-casting producers. You can do this by simply keying the key words" Aluminum die casting makers" on the Google internet search engine.

Several of the questions you need to ask yourself are whether they have actually experienced and trained drivers, how much time their service has functioned, or if they have some success. You can commonly get the solutions to these questions from the manufacturer's site. You can investigate other websites or external sources to verify if the details offered on the supplier's website is genuine.

What Does Premier Aluminum Llc Mean?

One more thing you have to think about is the maker's ability to create light weight aluminum die-casting items. Simply put, the quantity of products the maker can produce at a provided time. Some of the essential questions you need to ask yourself are whether the maker can create a higher quantity or can the supplier fulfill your demands.

(https://premieraluminum.edublogs.org/2024/12/12/top-rated-aluminum-casting-company-why-premier-aluminum-llc-stands-out/)What happens if your business calls for 10,000 pieces of particular maker parts from the supplier within one month? You ordered this quantity; nonetheless, the producer can only generate 5000 items of these maker components within one month (Aluminum Castings). As an outcome, you will not have the ability to obtain the quantity that you purchase in a timely manner

The Ultimate Guide To Premier Aluminum Llc

It is important that you should inquire if the producer is applying an in-house tooling procedure. Furthermore, you have to ask the manufacturer exactly how a lot the price of internal tooling is. The in-house tooling process, which permits you to create distinctive designs and shapes can be an additional price.

This aspect straight correlates with the maker's manufacturing capacity. You have to search for a maker that can ensure quicker delivery of products. Nonetheless, this should be performed in such a means that high-quality criteria are preserved. This can guarantee that you can get your items on schedule, and you can prevent missing out on those important service chances.

This implies that there are numerous options that you can choose from. Today, consumer demands maintain on changing. It seems that customers are looking for an outstanding mix of top quality, cost-effectiveness, and sturdiness. That is why it is significantly advised that you should choose a supplier that can create different types of light weight aluminum die-cast items.

Get This Report about Premier Aluminum Llc

Many frequently, these light weight aluminum die-casting products will certainly require some decorations, machining, or completing touches. Having this in mind, you should seek a manufacturer that can carry out a selection of additional ending up jobs when pass away spreading is done. Some examples of ending up operations consist of Chromating, CNC Machining, Sandblasting, Powder covering, Anodized, E-coating, Damp paint, Plating, and a lot more.

Pass away casting is one of the most economical, precise, and protean manufacturing processes in the world minute. The procedure includes fitting molten significance, under pressure, into an appropriate die (planet), and previously solidified it can be expelled and completed (if necessary) in a range of ways. Report this page